Wayne Barrett has been building boats for 50 years, many of them world renowned. His latest venture is a DIY trimaran kit that embodies his half-century of expertise and celebrates “the joy of building and sailing your own creation”.

Famed in multihull circles and the creator of high profile vessels such as ‘Trilogy’ and ‘Indian Chief’ designed by Tony Grainger, and ‘Traveller’, the 50-foot tri designed by Dick Newick, Barrett describes himself as “a little guy designing boats on the kitchen table in an apartment on the Gold Coast, with a nice view over the lake”.

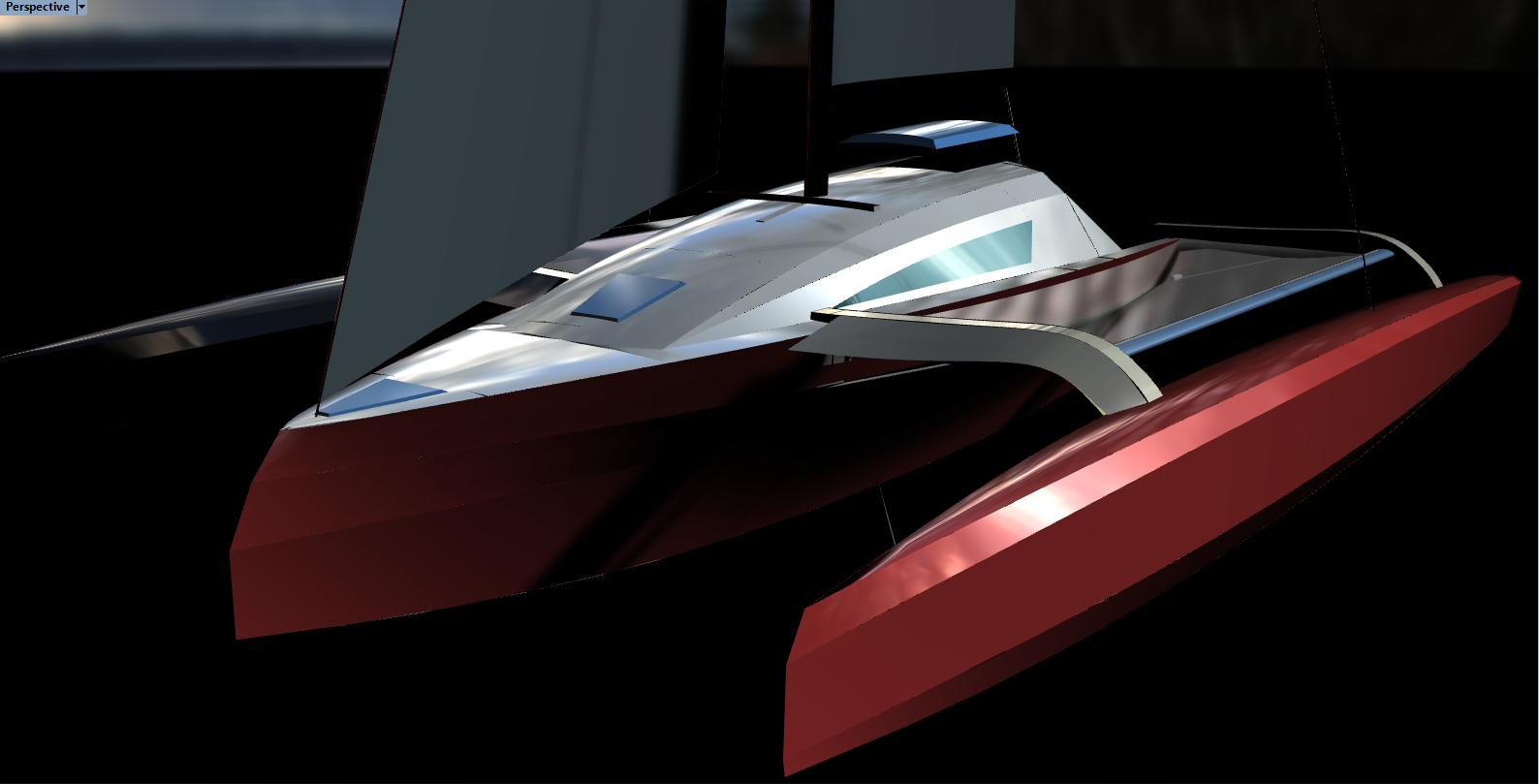

He has built some “100 or so boats” over the years and his passion and prowess have inspired him to create the M80 trimaran, an 8-metre vessel designed with the home builder in mind; those with limited time or space, and some basic experience with hand tools.

The versatile M80 can be specified for cruising or racing and the larger 9-metre design will have a range enough to sail across the Atlantic.

“In 2021, I’m planning to sail the 8-metre boat up to The Whitsundays as a promotional exercise to showcase the vessel. It’s very manageable for single-handed sailing.”

The concept arose from Barrett’s belief that sailing should be within everybody’s reach.

“I’ve built quite a few complicated, high-performance multihulls over the years and I’m aware they consume time that’s way beyond what an amateur could devote to a build. I used the flat panel concept, adapted to tri design and put it out there for amateur or professional builders.

“A friend of mine I’ve been sailing with for 40 years needed a new modern Buccaneer 24, a plywood 24-foot Crowther around in 1966. I’ve built a few of them, and a B33, B40 and a Spindrift 37. I thought about it for a year or so, then did something about it.

The spiritual successor to the Crowther Buccaneer 24, the 24-ft ‘Mojo’, was originally designed with a central cockpit, a double bunk down aft and a galley and head forward, which I thought was a great concept. But I scrapped that idea and went with a conventional aft cockpit.”

The first boat, in Brazil, set sail just over three years ago and since then, Barrett has sold plans around the world.

“A mate of mine from Geelong, Andrew Johnson, is building one at Lightwave Yachts at Coomera on the Gold Coast with the guidance of Roger Overell. It’s well into the final stages and will be used for cruising. It’s made totally from carbon, so it’s light and strong.

“There’s another one being built in France, a 6-metre design being built in Melbourne and a 9-metre design close to completion in The Netherlands. I’ve sold 9-metre plans to Germany and one in Sydney, revised to be all flat panel, foam and round bilge, with aesthetics to suit that owner.”

The main attributes of the design that have such broad appeal are its simplicity and economical package.

“Initially the concept was built around plywood, which has been a common material for 100 years and most people are familiar with it,” explained Barrett. “The benefit of ply is that a guy can build it in his own shed, over time. But other than the 9-metre in The Netherlands, people are all keen on the foam and epoxy.

“Foam and epoxy is a bit more costly, but comparing the total price is attractive for an amateur builder. It can be built from CNC cut panels in a fraction of the time compared to some other options, alternatively you can build it from our easy to follow plan set for DuraKore, DuFlex or foam core kits.”

Barrett has worked with ATL Composites for the past 25 years on numerous projects, including the 9.2-metre ‘Trilogy’, which held the Aust Championship title for around 10 years, ‘Traveller’ and the 13-metre Gary Lidgard-designed cat ‘Saloon Bar’.

“I also built a 7.5-metre caravan which appeared on the ABC program, ‘New Inventors’ five or so years ago,” continued Barrett. “I used ATL Composites’ products, including foam and resins.

“ATL spent a lot of time scanning the surface of the moulds so we could get an accurate pattern for the shapes of the foam core. I built five of them, all custom designed and built, all traveling the country. It was a fantastic looking thing!

“ATL has always been fantastic to me, in their general support, timely supply of goods, always bending over backwards to help.”

For the M80 in build at Lightwave Yachts, the main shell structure, fore and side decks, and cabin sides were built with DuFLEX/foam panels cored with Divinycell H80 structural foam in a variety of thicknesses and reinforced with double bias E-Fibreglass skins.

The cabin top and floats were strip planked with DuFLEX H80 strips with a 450grm uni-directional on either side to achieve the compound shapes and then reinforced with additional laminates to complete the structure.

The project incorporated carbon fibre and E-fibreglass reinforcement, supplied by ATL, to provide stiffness and to achieve the weight specification for the project.

High performance KINETIX R246TX, a thixotropic epoxy, was used to laminate these reinforcements and WEST SYSTEM R105 and H206 was used for all bonding and coving, combined with WEST SYSTEM 413 Microfibre Blend and 411 Microsphere Blend powder modifiers to alter the consistency for the specific applications.

The M80 was faired with ATL’s unique Technifill XP which is a pre-filled epoxy fairing compound that is ultra-lightweight and very easy to sand.

Getting started is straightforward, according to Barrett. “People buy the plans, complete with DXF files and they can have all the flat components cut out with CNC or jigsaw by hand.

“If you have plenty of time, it’s cheap. An average handyman or woman, with basic experience with hand tools could put it together in their garage or workshop. In The Netherlands it’s being assembled under a tent to keep rain and snow out. Where there’s a will, there’s a way to boat the world over.”